Between 14 December 1968 and 5 January 1973, there were sixteen premature explosions of projectiles in Navy large caliber guns23 24. A number of sailors were killed or wounded in these accidents and the ships were forced to leave the firing line for repairs. In general, the detonation of a projectile in the gun barrel is caused either by a faulty fuze or by a sensitive explosive load. Faulty projectile base closures and missing gas seals around the base fuze can cause in-bore reactions but this cause is generally more uncertain.

In-bore projectile explosions have been produced in laboratory trials by introducing gross defects in the base of the projectile. Removing base closure plug, removing the copper seal from around the base plug, and drilling holes through the base plug has caused some in-bore reactions. These major defects in the hardware would be hard to miss in production inspections and during normal projectile handling operations however.

To remove the danger of fuze malfunctions in projectiles and other munitions the DOD had, some years earlier, issued Military Standard 1316.25 This Standard requires, among other things, that two independent safety features be built into the fuze to prevent premature arming. Each feature has to be derived from a different environment. For example, the gun setback forces should not defeat both safety features. No similar safety standard was written for the explosive load.

MIL-STD-1316 requires that safe separation distances be achieved before the fuze can arm. Properly implemented this requirement should eliminate fuze action as the cause of in-bore premature explosions. Composition A-3, the explosive of choice used in most Navy 5-inch projectiles at that time was not considered a problem that would cause in-bore detonations. Many of the Navy gun experts did not believe that a high explosive alone could be the cause of the in-bore premature explosions.

In a four-month period, between 9 July 1969 and 7 November 1969, there were four in-bore detonations of Navy 5-inch gun projectiles. In each case, the barrel was either ruptured or completely severed. Also, in each case, Composition A-3 was the main explosive charge used in the projectile.

In November 1969, the Navy organized an Ammunition Special Study Group under RAdm. Frank H. Price, Jr. to conduct a complete investigation of the 5-inch gun malfunctions. The Study Group consisted of three subgroups, Quality Assurance, Metal Parts, and Explosives. The Explosives subgroup set out to demonstrate that the set back forces experienced during 5″/54 gun firings could be the cause of the prematures. If the explosive charge in the projectile was not pressed to the correct density, it could collapse and rapidly compress the air in a cavity. We in the explosives community believed that the adiabatic heating of the air could cause unfuzed Composition A-3 loaded projectiles to detonate in the barrel and destroy the guns.

The Explosives subgroup designed and performed a series of experiments where both the density of the explosive charge and the size of base gaps in the projectile were varied. The projectiles were unfuzed and the metal parts were inspected carefully to assure that there were no defects that could cause the explosive charge to detonate.

Between 15 December 1969 and 9 March 1970, thirty-two 5-inch/38-caliber gun barrels were destroyed in the Ammunition Special Study Group’s tests at the Naval Surface Warfare Center Dahgren, VA. These 5″/38 guns had been modified to fire the same 5″/54 projectiles that had functioned in-bore in the Fleet. In each case, the gun barrel was severed somewhere between 40 and 80 inches from the breech.

As we had theorized, a combination of low-density explosive loads and gaps at the base of the projectile resulted in detonations on gun-launch. Upon inspection by the Quality Assurance Group, these defects were found to exist in a number of the projectiles issued to the Fleet. The low density was due to defective loading procedures used at the factory to press the explosive into the projectile bodies. The base gaps were in some cases due to value engineering changes to the projectile metal parts and in other cases, to the replacement of the original base fuzes with shorter ones leaving a gap at the end of the fuze.

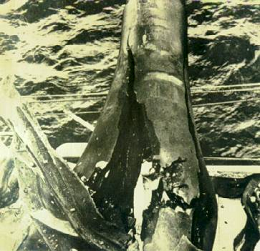

The picture shown below is that of the 5-inch/54-caliber gun barrel on the HMAS BRISBANE26 after the July 1969 in-bore detonation of a Composition A-3 loaded projectile. The Australian Navy experienced one in-bore detonation out of approximately 38,000 HC-PD MK-41 Mod 0 5″/54 U.S. Navy projectiles fired. Between 1965 and 1969 the U.S. Navy fired about 2,891,000 rounds and had 6 in-bore prematures.

Sensitive explosives like Composition A-3 and Composition B are not very forgiving when there are defects such as voids or low-density regions present in the charge. Adiabatic heating resulting from the compression of the explosive as the projectile is accelerated in the gun barrel can ignite these explosives and cause in-bore detonations.

This resulted in a Navy program to investigate the use of castable PBX compositions in large caliber projectiles.

The explosion, on 1 October 1972, in an 8-inch “bag gun”27 aboard the heavy cruiser, USS NEWPORT NEWS, deserves special mention. The projectile, loaded with Explosive D, detonated in the ram position in the gun chamber. The accident was attributed to a premature fuze action. The explosion ignited the powder bags in the turret. Fire and combustion gases propagated down the powder hoist. The tubes around the hoist were ruptured and the combustion gases vented into the bowels of the ship. Twenty sailors died as a result of the explosion or by asphyxiation due to the burning propellant gases.

At about this time, the U.S. Army had begun work on the development of HMX and RDX based gun propellants to reduce the vulnerability of tank ammunition. LOVA (LOw Vulnerability gun Ammunition) is the acronym used by the Army to identify these nitramine-based propellants. These formulations were similar to the Navy PBXs. Like the PBXs the LOVAs were hard to ignite and they either extinguished or burned slowly at atmospheric pressure.

LOVA propellants were showing promise as a way to reduce the vulnerability of tanks and other combat vehicles. Naturally, after the USS NEWPORT NEWS accident, the Navy became interested in the Army LOVA work and initiated a complementary effort at the Naval Ordnance Station, Indian Head, MD.28

23Beauregard, R.L., History of Navy Use of Composition A-3 and Explosive D in Projectiles, NAVORD TR 71-1, 1 January 1971.

24NAVORD ltr. ORD-0332D: EWA of 10 November 1972; Subject: Revising of NAVORD TR 71-1, History of Navy Use of Composition A-3 and Explosive D in Projectiles.

25MIL-STD-1316D, “Fuze design safety criteria for” issued 9 April 1991.

26One of these in-bore projectile detonations occurred aboard an Australian Destroyer, the HMAS BRISBANE, as she was firing 5-inch/54 caliber guns and ammunition purchased from the U.S. Navy.

27A “Bag Gun” is one that uses a propelling charge that is not contained in a cartridge case fixed to the projectile. The propellant is contained in combustible cloth packages that are added after the projectile is seated in the bore of the gun.

28The Naval Ordnance Station, Indian Head has gone through a series of name changes over the years. As of this writing, it is called “The Naval Surface Warfare Center, Indian Head Division, Indian Head, MD. The new name will be used in the remainder of this document.